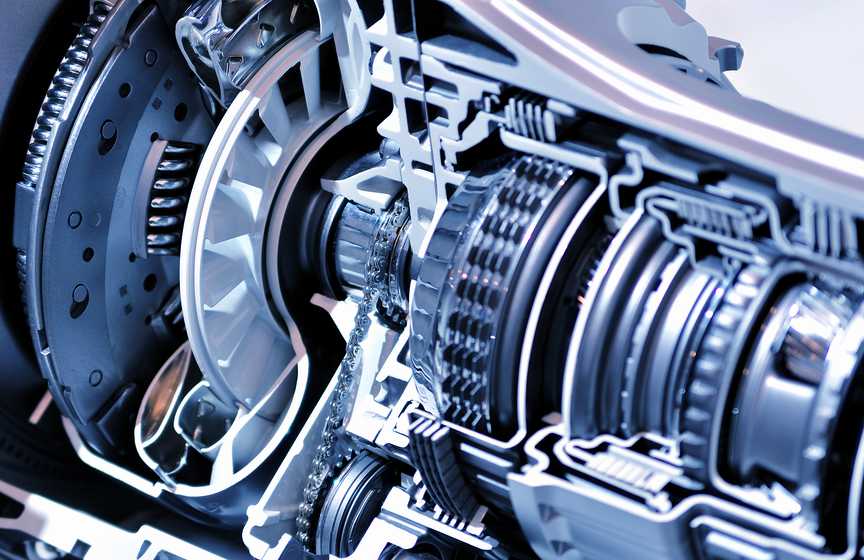

Automotive Testing

Get accurate measurements of strain, pressure, and vibration under extreme testing conditions

Automotive testing often occurs under harsh conditions that can wreak havoc on measurements. Strain, pressure, and vibration sensors contend with temperatures that can exceed 500°C. Special high-temperature strain gages are welded or bonded to the test article using ceramic cement. High-temperature piezoelectric accelerometers measure vibration. Exhaust pressure measurement for diagnosing combustion instabilities may require recessed mounts and sensing tubes to protect pressure sensors from the heat. Each sensor presents special problems that the signal conditioner must address to ensure accurate data can be collected.

Meeting the Challenge of Automotive Test Measurements

Dynamic Strain Measurements

Strain gages that measure dynamic strain at high temperatures require special alloys for leads. The temperature increase at engine startup causes lead resistance changes of tens to hundreds of ohms. A gage’s substrate may break down, causing leakage. Precision Filters’ Balanced Constant Current (BCCTM) technology makes the circuit insensitive to temperature-induced changes in lead resistance and uses only a two-wire connection to the gage. Because the circuit is balanced, the differential input amplifier rejects noise pickup in the leads. And if a gage terminal shorts to the test article, the circuit continues to measure strain.

Pressure Measurements

When measuring pressure in applications where the sensor cannot be flush-mounted with the exhaust system flow field due to temperature extremes, the sensor is often recessed at the end of a tube. The tube produces an organ-pipe resonance, which amplifies the pressure signal by 20 dB or more. This resonance limits the useful measurement bandwidth to about 20% of the first resonance—about 1 kHz for a 1" tube. Precision Filters and Kulite Semiconductor Products developed the patent-pending REZCOMP™ technology to extend the frequency response of pressure sensors in real time, with no need for post-processing.

Vibration Measurements

High temperatures complicate the task of measuring vibration. Charge amplifiers condition piezoelectric accelerometers: at temperatures above 500°C, accelerometers often have extremely low insulation resistance across the piezoelectric sensing element. Using a general-purpose charge amplifier could result in low-frequency gain peaking as high as 20 to 30 dB—causing excessive low-frequency noise, gain errors, or even total saturation of the charge amplifier. Precision’s vibration amplifiers are compatible with high-temperature accelerometers and exhibit minimal peaking—even with accelerometer shunt resistance as low as 10 kOhm.

System and Sensor Health

In addition to the challenges discussed above, sensors are often inaccessible and hard to troubleshoot. Regular system and sensor health checks are an important part of the measurement system verification process. Without the aid of automated techniques, system and sensor verification can be a daunting and laborious task. Our signal conditioning systems have built-in hardware and software that provide a series of automated sensor, circuit, and cable checks at the push of a button. Precision Filters' signal conditioning cards facilitate real-time monitoring of sensor and cable health, measure and report cable roll-off, and detect insulation leakage.

Precision Filters’ Systems for Automotive Testing

Precision Filters’ range of products can support any installation, large or small. Companies have relied on Precision Filters products for testing engines and powertrains, aerodynamics in wind tunnels, NVH, wheel balance, and more.

28000 Signal Conditioning System

Ideal for test cell applications, our versatile 28000 system features built-in NIST traceable self-test for performing annual calibrations and automated pre-test go/no-go tests for run-time system verification. The 28000 includes a complete line of signal conditioners suitable for dynamic or static measurements and able to accommodate any transducer: voltage, charge, static or dynamic strain, as well as bridge-type transducers such as pressure sensors, piezoresistive accelerometers, load cells, and more.

Filter/Amplifier Systems

For low channel count configurations, choose the economical two-channel PFA-2 filter/amplifier or the eight- or sixteen-channel PF-1U-FA filter/amplifier. Both are compact, highly programmable, and offer flat/pulse low-pass filter technology both time- and frequency-domain measurements.

Learn more about the PF-1U-FA Multi-Channel Programmable Filter/Amplifier System »

or the

C Series Signal Conditioning Modules

Our high-performance C Series signal conditioning modules are rugged, portable systems that integrate seamlessly with National Instruments’ CompactRIO and CompactDAQ chassis, making them ideal for in-vehicle installations or installations close to the device under test.

Learn more about the Precision C Series Signal Conditioning Modules »